DuraKraft™ Finishing Process

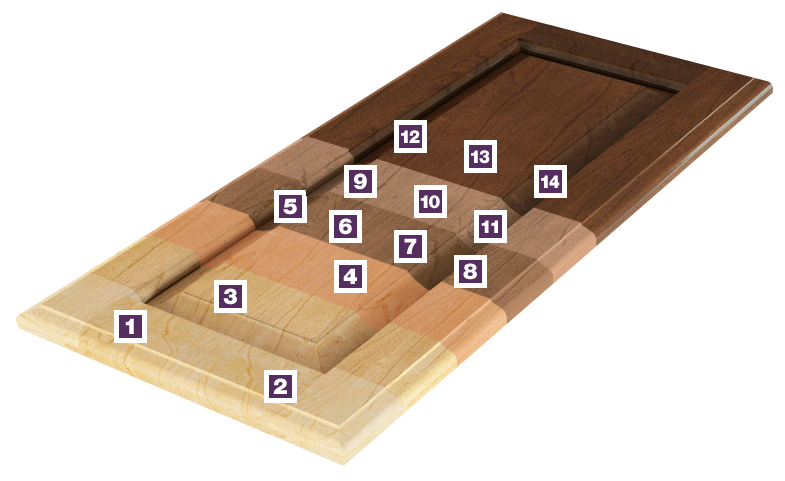

14-step finishing process:

All KraftMaid wood doors and drawer fronts receive KraftMaid’s 14-step finishing process, resulting in one of the finest finishes in the industry. From the initial sanding to the final finish application, each piece of cabinetry is made to your exact specifications by our skilled craftsmen.

KraftMaid Cabinetry selects quality wood, which skilled craftsman sand to a smooth finish.

After sanding, all surfaces are vacuumed to eliminate dust particles.

Craftsman hand-apply distressing, vintage and burnished techniques to selected finishes. Craftsman hand-apply distressed, vintage and burnished characteristics to select finishes.

Equalizer stains are applied to balance the base color of the wood.

Toner is applied which establishes consistent color uniformity.

A deep penetrating stain is (hand-applied/hand-sprayed/applied) to reveal the wood grain.

All stained surfaces are evenly hand-rubbed and wiped clean of excess stain.

After slowly air drying, highlights, glaze, glaze details, burnishing stain, and vintage patina are hand-applied to selected finishes.

KraftMaid's Cabinetry's specially formulated wood sealer is applied, penetrating all exposed wood surfaces for uniform protection.

Sealed product is placed in high-temperature oven to ensure a thorough cure.

All surfaces are hand-sanded again, providing a smooth, consistent surface to accept topcoat.

Environmentally safe DuraKraft™ catalyzed topcoat is applied to maximize resistance to scuffing, dents, moisture, UV fade and household chemicals or agents.

Top-coated pieces are slow-cured in a 150-degree oven, creating a smooth, baked on surface.

Each cabinet is inspected and hand-polished, assuring quality and durability.

Patented

14-step FINISHING PROCESS

Patented

14-step FINISHING PROCESS

Step 01

KraftMaid Cabinetry selects quality

Step 01

KraftMaid Cabinetry selects quality  Step 03

Craftsman hand-apply distressing,

Step 03

Craftsman hand-apply distressing,  Step 05

Toner is applied which

Step 05

Toner is applied which  Step 09

KraftMaid's Cabinetry's specially

Step 09

KraftMaid's Cabinetry's specially Step 12

Environmentally safe DuraKraft™

Step 12

Environmentally safe DuraKraft™